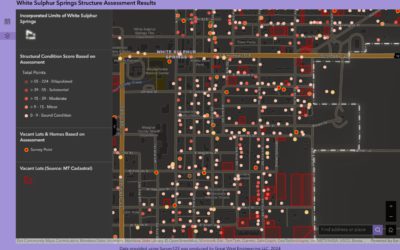

Basin Creek Dam #1, is nestled in the foothills of the Highland Mountains about 10 miles south of Butte, Montana. The reservoir serves as a critical source of municipal drinking water for the City-County of Butte-Silver Bow (BSB), providing nearly two-thirds of the City’s supply. Constructed in 1897 by the Butte Water Company to support local mining operations, the dam also serves a variety of other purposes, including flood control, irrigation, and habitat preservation. Originally an 88-foot-high, 275-foot-long masonry structure made from granite blocks, the dam has undergone multiple upgrades over the years. In 1913, a height increase raised the dam 13 feet by constructing a concrete cap and supported the original granite blocks with monolithic concrete tiers on the downstream face. In the 1930s, modifications added earthen fill on the downstream side of the dam to minimize concrete deterioration. Over the next 90 years, other small improvements were made, but the overall configuration of the dam has not significantly changed.

Original Construction of Basin Creek Dam #1

Upstream Dam Face Before Rehabilitation with Cracking

Concrete Pump Truck with Over 150 ft Reach to Access Dam Face

However, by 2019, significant cracks and deterioration in the dam’s upstream face prompted concerns about its stability, particularly when the Montana Department of Natural Resources and Conservation (DNRC) warned that failure to address the issues could lead to reservoir-level restrictions. In response, BSB commissioned Great West Engineering to draft a Preliminary Engineering Report (PER) in 2021, assessing the dam’s condition and proposing several repair alternatives. The proposed solution involved removing and replacing the existing parapet wall, partial removal of the concrete cap, and installing post-tensioned anchors to improve stability. With the design finalized in 2023, a contractor was selected and the construction began in April 2024.

The rehabilitation process kicked off with the removal of 300 cubic yards of deteriorated concrete using a concrete wire saw, a specialized tool that cuts through concrete with a diamond-embedded wire. The wire is continuously rotated around the material and is then slowly pulled through, allowing for precise controlled cuts. Due to limited access, barges were used not only to transport the concrete debris but also to serve as floating work platforms. Once the old concrete was cleared, the team started to pour the new dam face. A large, 61-meter concrete pump truck was needed to overcome the 80-foot elevation difference and 150-foot reach from the base of the dam to the crest. The new concrete was specially mixed to resist water, freeze-thaw impacts, and shrinkage while welded PVC waterstops were incorporated into the joints to prevent water seepage and future deterioration ensuring the dam’s longevity for years to come.

Drilling Equipment Transported by Barge to Dam Face

Construction Crews Drill Post-Tensioned Anchor Holes

The installation of post-tensioned anchors at Basin Creek Dam required the expertise of a specialized contractor. A post-tensioned anchor consists of a steel bar embedded through a structure, anchored at its base, and then tensioned to enhance its stability. This technique helps resist forces such as sliding, overturning, and bending that the dam may encounter over its lifetime. A total of 12 anchors were to be installed along the crest of the dam to ensure its continued safety and resilience.

To install the anchors, drilling equipment was used to bore through the existing concrete and granite blocks, reaching deep into the dam’s core. Given the remote location, barges were once again employed to transport a track-mounted drill rig across the reservoir. Once lifted onto the dam’s crest, the rig would begin drilling the holes necessary to install the anchors. After the holes were drilled a series of grouting, redrilling, and watertightness testing was completed on each hole to obtain a sealed anchor hole. As the holes were drilled, the contractor discovered significant voids between the original, hand-stacked granite blocks. These gaps allowed water from the reservoir to seep into the anchor holes, complicating the sealing process. Multiple iterations of grouting, redrilling, and watertightness testing were required before the holes were adequately sealed.

Eventually, the anchor holes were ready, and the installation of the steel anchor bars could begin. Designed with Class I corrosion protection, the bars were encased in corrugated HDPE sheaths and filled with grout to increase their longevity and durability. However, due to the rough terrain and difficult access, the bars and corrosion protection were at risk of being damaged during transport, potentially compromising their corrosion resistance. To mitigate this risk, the contractor adopted an innovative solution to minimize handling: helicopter installation.

The morning of the anchor bar installation was filled with anticipation to watch the helicopter work. A large group of stakeholders gathered on-site as a helicopter arrived from Bozeman at 8:00 a.m., landing at the park a quarter mile from the dam. The pilot, alongside the contractor, conducted a safety briefing and a walk-through of the site, safety plan and hand signals for communication. At 8:50, the first anchor bar was lifted into place, and from that point, the process moved swiftly and smoothly. Within just 40 minutes, all 12 bars had been installed, with the helicopter returning to Bozeman after refueling. The entire operation, impressively, took under two hours to complete.

Helicopter Post-Tensioned anchor Pickup and Dam Install

Once installed, the anchors required grouting to secure them in place and provide additional corrosion protection. Hydraulic jacks were used to tension each bar to its specified load, which, once locked off with anchor nuts and bearing pads, amounted to over 200,000 pounds per bar. Together, the 12 anchors now provide nearly 2.5 million pounds of additional force, stabilizing the dam and ensuring its resistance to sliding, overturning, and bending forces.

To an outsider, the work on the dam might have appeared to have stalled for months since all the concrete had been removed. The new concrete dam face was concealed behind forms on the upstream side of the dam, and the anchor work was hidden underground. But once the anchors were in place, rebuilding of the dam crest could finally proceed. More than 200 cubic yards of concrete were poured to form a new overlay, parapet wall, and stairs. The 125-year-old structure began to take on its fresh new look, complete with updated handrails.

In addition to the primary work, the project team leveraged a collaborative and trusting relationship between the Owner, Engineer, and Contractor to address a range of ancillary improvements. These included a new access bridge on the dam’s east side, upgrades to the east spillway, the establishment of three new benchmarks on the dam crest for better monitoring, improvements to the west access road, and the addition of a new concrete slab near the catch basin to enhance working conditions and facilitate future projects.

From the initial concrete cut on April 3rd to the final pour on October 15th, the project required intense focus and dedication from the team to complete. Over the course of the construction, more than 1,100 feet of anchor holes were drilled, 384 feet of post-tensioned anchors were installed, and 300 cubic yards of concrete were poured. These upgrades have significantly increased the structural integrity of Basin Creek Dam #1, ensuring its safety and reliability for years to come. We are proud to have been part of another chapter of this dam’s storied history. Check out the highlight video below!

LATEST NEWS

Kasey Ketterling Joins The Great West Engineering Team

We are pleased to announce that Kasey Ketterling has joined the Great West Engineering team in our Boise office. This marks an exciting opportunity for the local office as we continue to grow our municipal expertise by adding an experienced professional engineer and...

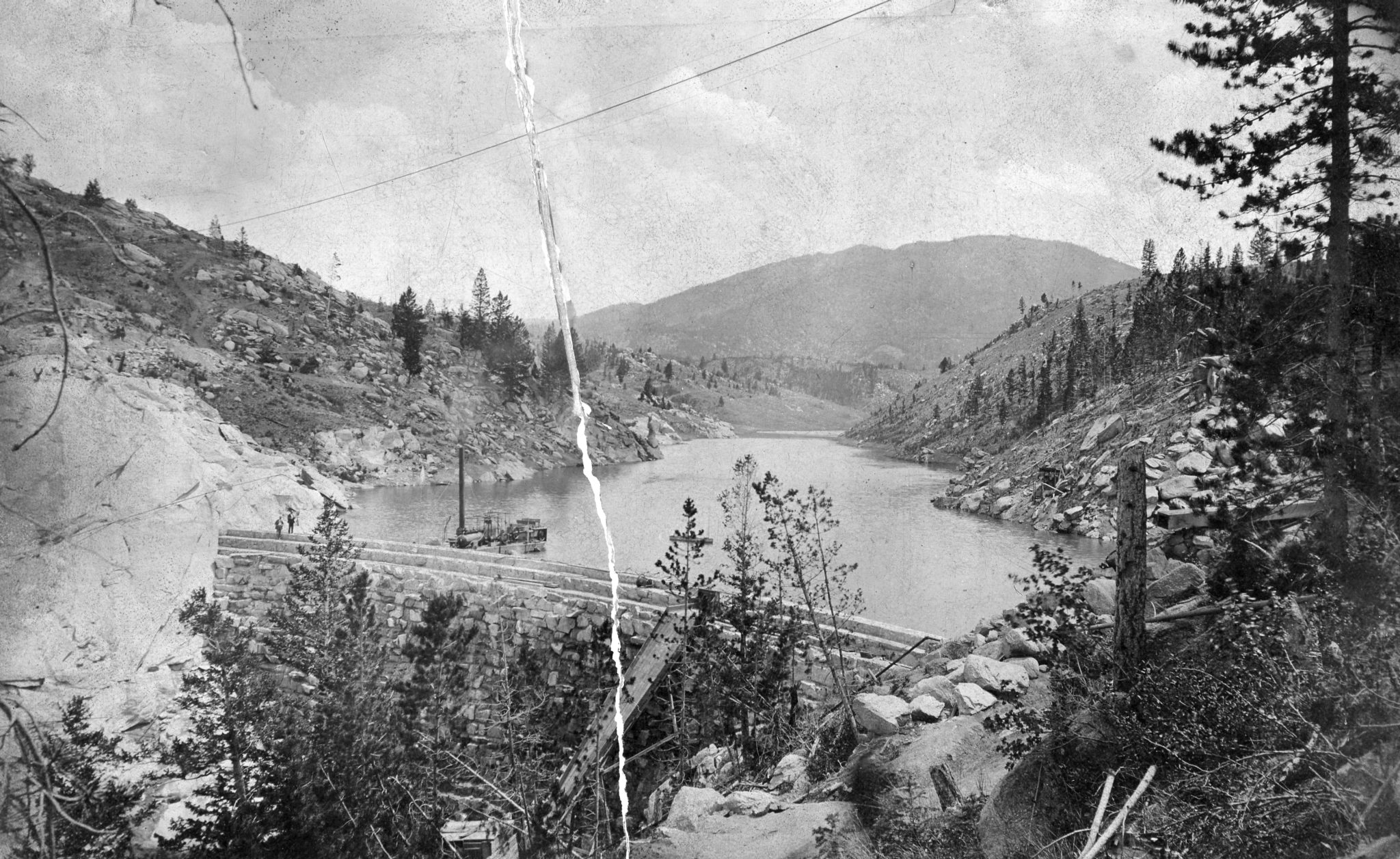

Beyond the Blueprint: How GIS Enhances Engineering & Planning Solutions

Geographic Information Systems (GIS) have become an essential tool for communities striving to make smarter, data-driven decisions. From infrastructure planning to public engagement, GIS provides a dynamic way to visualize, analyze, and manage data across a wide range...

Yearly ROSE Award Winners

At Great West Engineering, we take pride in recognizing the dedication and hard work of our team. Each year, the Recognition of Special Effort (ROSE) award honors employees who go above and beyond—those who step up, make a difference, and inspire those around them....