What is a Water Model?

A hydraulic water model is a computer simulation of a water system. The water model is a powerful tool that can help to analyze an existing system as well as help to narrow down alternatives for future improvements and/or evaluate proposed developments or improvements. Through the help of specialized software, such as WaterCAD, a community’s water distribution system is modeled as a “network” and allows for nearly as many details you want to input into the system, including pipe material, pipe size, length of pipe, etc.

Water Model Usage: Analyze Condition of Existing System

The model can provide a big picture look at how a system should be functioning (i.e. how much water is available at fire hydrants, what system pressure, how to tank levels affect the system, etc.). Too often, however, a model is left at the theoretical level when it is actually much more important to get real results. One of the best ways to determine the accuracy of a water model is to calibrate it with hydrant testing. An ideal hydrant test would involve flowing one hydrant at a time while recording the available flow as well as the pressure not only of the flowing hydrant but also of several other hydrants throughout the system. A handful of hydrants should be tested throughout the community. These results are then compared to the original water model to determine how well the theoretical matches with the real results. There can be numerous reasons for differences. A common issue is excessively aged and/or scaled pipe, which can create additional headlosses in the system. Or, sometimes, the results may indicate a physical problem in the distribution system itself such as a closed or stuck valve. Regardless, the hydrant testing is important to calibrate the water model, which ensures that when looking at future analyses, the results are most accurate for the system.

Water Model Usage: Determine Available Fire Flows

One of the most common uses for water modeling at Great West is to help communities determine available fire flows for their water system. This is an important consideration for all communities but may be most significant for small systems as fire flow demands are typically much larger than their projected customer demands and as a result drive the overall size of the system. Water modeling can not only identify fire flow deficiencies for a system but can also be used to evaluate alternatives to improve fire flow as part of future fire flow improvements. The model can help determine which pipes need to be upsized and to what size. The model can also be used to help prioritize improvements by determining which improvements will have the most significant hydraulic benefits to the system.

Water Model Usage: Analyze System Pressures

A hydraulic water model helps to evaluate system pressures. Determining where pressures may be deficient and under what conditions (i.e. with a particularly pump running or not running, or when tank levels drop, etc.). The model can determine where pressure zones may need to be added or modified. Similarly, it can help to determine what elevations of new tanks should be.

Water Model Usage: Determine System Adequacy for New Development

Another common benefit to water modeling is to evaluate impacts on the system from proposed developments and/or connections to the system. Can an existing system handle a new connection at the proposed location? If not, what improvements can be done to the existing system to make the new connection acceptable? All of these questions can be answered with an accurate water model.

Water Model Usage: Prioritize Improvements and Save Money

In addition to looking at the existing system, the water model has a function which allows the user to add alternatives right into the system. The model of the existing system remains in tact while the user can make changes to the system in separate “scenarios” to simulate what the results of various improvements may be (i.e. upsizing a pipeline, looping the distribution system, adding a pressure zone, etc.). With input from the client as to what the desired end results are, the model can help to identify the most economical improvements that will provide the best end result for any particular system.

Water Model Usage: Is it Time for an Updated Water Model of Your System?

How well do you understand your distribution system? Do you have a long term plan to improve your system? Can a hydraulic water model help you develop a more cost effective replacement plan?

A little extra time and money invested in a properly developed water model can be the difference in completing cost effective, phased improvements that are improving the overall system versus wasting large sums of money doing improvements that are not going to help meet the desired end results.

Article by Crystal Bennett, PE

Have Questions?

LATEST NEWS

Spreading Holiday Cheer: Great West’s Tradition of Giving

As we look forward to the holidays, one of the highlights of the season is fundraising and helping local families in need. An annual Great West tradition since 2015, it’s incredibly special to see our staff come together and donate to support local families in the...

Happy Holidays From Great West Engineering!

As snowflakes dance and lights twinkle, the spirit of the holidays is upon us! At Great West Engineering, we cherish this magical time of year, celebrating not just the season but also the incredible journey we've shared with you. This year, we've wrapped...

The Importance of Preliminary Engineering Reports/Facility Plans

Facility Plans and Preliminary Engineering Reports (PER) are planning documents essential to a community’s decision-making process for major infrastructure improvements. These documents are critical not only to help a community plan and prioritize projects, but they...

Company News

Updates and News From Great WestWE ARE HERE AND WORKING FOR YOU!

Please be assured that the full staff of Great West Engineering continues to work hard on your behalf. The health and safety of our employees, clients, and the communities in which we work are of paramount importance. We continue to encourage our staff to work...

ROSE Award Winners!

We are pleased to announce our latest ROSE Award winners! Billings Office Winner: Crystal Bennett, PE What her peers said: Crystal was a true warrior in working very hard on the construction of the Laurel and Big Timber projects and greatly assisting the office with...

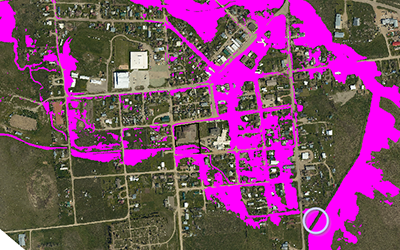

Levee Accreditation Feasibility Study

Montana’s small towns face many challenges. One of which is striking a balance between supporting growth and development while maintaining affordable infrastructure, housing, and community facilities. Within Carter County, Ekalaka is the only community with public...

Mill Creek Fish Ladder

Project OverviewIn the Fall of 2019 Great West Engineering, in conjunction with Montana Fish Wildlife & Parks (MTFWP) and Trout Unlimited (TU), successfully designed and installed the first fish ladder in Great West’s history. The new fish ladder was installed on...

Still Here For You

As the Country continues to battle the COVID-19 Pandemic, we want you to know the Great West team is still here for you. We continue to provide responsive client service and deliver quality projects. Though we are encouraging our staff to work from home, our...

Great West Engineering Response to COVID-19

The health and safety of our employees, clients, and the communities we work with are very important to us. As a result, we are joining others in taking active steps to help prevent the spread of the coronavirus, COVID-19. Effective immediately, we are suspending...

Idaho Rural Water Presentations

Missed the latest IRWA conference or just want to review the presentations given by Great West Engineering? We've got you covered, please see below for our teams contribution to the conference. How to Hire an Engineer - Presentation by Andrew Kimmel, PE Introduction...

Great West Engineering Wins 2019 Employer of Choice® Award!

Great West Engineering Wins 2019 Employer of Choice® Award!Great West Engineering has been named a recipient of PSMJ’s 2019 Premier Employer of Choice® Award! The award is based on data collected from a 70-factor survey completed by employees of engineering and...

Future Is Bright With New Wastewater Plant

The City of Cut Bank is poised for economic growth and well positioned to meet ever changing and stringent wastewater regulations with a new, “state of the art” treatment plant. A few side benefits include cold weather resilience, treatment process flexibility and...

Great West Gives Back!

We are proud to announce we were able to help four families in need this holiday season! Funds raised through donations from our staff were used to make sure each family gets to experience what the holiday season should be. Thanks to all who donated and helped with...