The City of Glendive provides water to residents, businesses, and commercial users. The water system is comprised of a distribution system, booster pumps, and a water treatment plant. Water from the Yellowstone River is treated and distributed to approximately 5,500 water users. The City of Glendive has utilized its existing water treatment plant for over 100 years. Initially constructed in 1916, the plant was extensively renovated in 1959. In the last 25 years, additional upgrades have included a new sludge handling system, upgraded filters, and new chemical feed systems. A new intake and an expanded chlorine contact basin were constructed in 2000. Despite the upgrades, several deficiencies remained, and the City moved forward with a large-scale project.

The Glendive WTP is one of two lime softening plants in Montana. The water quality of the Yellowstone River can be very challenging to treat as it can change quickly and dramatically. Turbidity ranges from under 6 to over 10,000 NTU. In addition to turbidity, hardness and alkalinity were also a concern. The treatment process used produces high-quality water. Therefore the City did not want to change treatment processes due to the success of its system. Improvements were designed to ensure that the City would not need to make capacity upgrades in the future, meeting the 5 MGD demand today and the estimated 8 MGD in the future.

Water Treatment Plant Before Improvements

The project included the demolition of a deteriorated building to make room for the installation of two new solids contact units/high rate clarifiers (SCUs). The new SCUs were designed to work within the existing hydraulic grade of the plant with no additional pumping. The project also included the installation of new piping to and from treatment processes, installation of new chemical feed equipment and chemical storage, upgrade of the lime slaker and associated equipment including a new lime silo and slurry feed system, replacement of the piping and valves in the existing filtration building, construction of a new electrical room, complete replacement of all electrical equipment, replacement of all process control equipment, installation of new pumps and VFDs to serve the distribution system, and installation of new energy-efficient windows in the filter building. All components were integrated into a new SCADA system to allow fully automated water treatment plant control.

New SCU Building

Construction of the SCU

Pipe Gallery in Filter Building

“Not only are we very proud of our new water treatment plant, but the fact that Montana is rationing water, Glendive is the only Town in the State that’s not rationing water. There’s a reason, we’ve got plenty of clean, fresh water for everybody and well into the future.”

Mayor – City of Glendive

During construction, the City had to continue to use the old equipment to produce water for the citizens of Glendive. During the startup of the new equipment, both the new and old equipment was used as necessary. The City of Glendive, Great West Engineering, and Swanberg Construction worked together, resulting in the City not experiencing any downtime that was not coordinated in advance.

The two new SCUs are 55-foot in diameter and 23-feet deep and were installed in a new building. The building includes a loading dock for chemical delivery, chemical storage room, electrical room, lime slaker room, chemical feed area, inline recarbonation room, pipe gallery with chemical injection points, and sludge removal system. The replaced chemical feed systems include alum, lime, polyphosphate, power-activated carbon, and various polymer feed systems. The injection locations were modified to ensure maximum contact time and to minimize the chemicals needed. The intermediate pumps and high service pumps were all replaced.

The lime feed system was upgraded to the Chemco packaged feed system. It provided the treatment needs and minimized the maintenance while being easy to operate. The Chemco system is a detention slaker and is cleaner than the conventional slaker as it has built-in grit removal.

The design also incorporated an inline recarbonation unit for pH adjustment to replace the old basin and diffusers, saving space and lowering costs. Instead of installing large basins with aeration, a TOMCO2 pressurized inline recarbonation system was utilized. The equipment has a small footprint of only 4-feet x 3-feet x 5.5-feet, and no retention basin was required. The pressurized system is at least 95% efficient (approximately 15% more efficient than the diffuser system).

The filters were overhauled and reconstructed to meet current design standards. The underdrain system, backwash, media, and controls were replaced. An air scour was added to replace the old surface washer system allowing the filters to treat additional flow comfortably. Close coordination of pipe replacement, air piping installation, filter media removal, replacement, and concrete work for the new underdrains and air scour was necessary to ensure a tight schedule was adhered to.

The filter building was also upgraded by replacing all pipe in the pipe gallery, pipe penetrations, valves and actuators, instrumentation, and high service pumps. A new electrical room was added to the filter building to ensure all electrical equipment met the current code. The addition was 15 ft x 30 ft and allowed the design team to move all electrical equipment out of the basement and away from potential flooding.

The plant continues to operate in a familiar manner for the operators as it is the same treatment technology that the City has operated for over 100 years. The new controls and added safety features of the upgrades have enhanced the operation of this plant. With the experienced operators understanding the treatment process, the startup and operation of the system were seamless. Their many years of knowledge and experience were invaluable assets to the City during this project.

To find out more about the projects or how Great West can assist your community with its infrastructure needs, contact us today.

LATEST NEWS

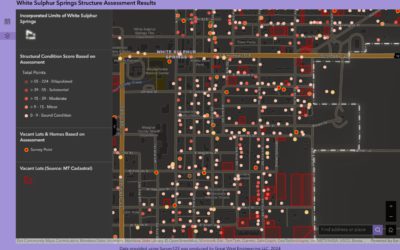

Beyond the Blueprint: How GIS Enhances Engineering & Planning Solutions

Geographic Information Systems (GIS) have become an essential tool for communities striving to make smarter, data-driven decisions. From infrastructure planning to public engagement, GIS provides a dynamic way to visualize, analyze, and manage data across a wide range...

Yearly ROSE Award Winners

At Great West Engineering, we take pride in recognizing the dedication and hard work of our team. Each year, the Recognition of Special Effort (ROSE) award honors employees who go above and beyond—those who step up, make a difference, and inspire those around them....

Why Transportation Planning Matters

Transportation planning is the collaborative process of evaluating the current state of a transportation network at a local, state, or regional level, identifying future transportation needs, and outlining implementation and funding strategies to align with...