FROMBERG WASTEWATER SYSTEM IMPROVEMENTS CASE STUDY

Many small communities in Montana operate discharging lagoon systems for wastewater treatment and as their discharge permits get renewed, they are seeing more stringent and additional limits that must be met. Unfortunately, because lagoons are natural systems, their performance is complicated and impacted by many factors. The original design of these lagoon systems was typically done with the intent of meeting permit limits related to national secondary standards for BOD and TSS, and even still, lagoons often struggle to provide consistent and reliable removal of these contaminants, let alone more stringent standards for such parameters as Ammonia, Total Nitrogen, or Total Phosphorus. These small communities are faced with the challenge of providing system improvements that are not only economically and technically feasible, providing long-term solution to the issues at hand, but also with developing a solution that they can effectively operate and maintain with the limited resources available to them.

The Town of Fromberg found themselves facing these challenges and entered into an Administrative Order on Consent (Consent Order) with the Montana Department of Environmental Quality in 2012 after receiving several violations related to poor performance of their existing lagoon system. The Town hired Great West Engineering to complete a Preliminary Engineering Report (PER) to address the Consent Order and the Town’s own concerns with the wastewater treatment system

Through an analysis of Fromberg’s discharge permit, Great West determined there is reasonable potential for the Town’s future permit to include an ammonia limit. While lagoons will nitrify and produce low effluent ammonia concentrations under certain conditions, particularly in the warmer months of the year, as wintertime cools the wastewater, the ponds will cease to nitrify, and ammonia removal will not be achieved. The Town was very interested in finding a solution that would allow them to continue the use of lagoon technology, versus upgrading to a more complex mechanical treatment plant to achieve compliance.

After consideration of several alternatives, ultimately the Town selected the Submerged Attached Growth Reactor (SAGR) system as its preferred solution. The Town’s Public Works Director and representatives from Great West visited several sites at which the SAGR had been implemented. The Town was impressed by how well the SAGR systems were working and by the exceptionally low operation and maintenance requirements. Operation and maintenance responsibilities and costs are a significant consideration for communities such as Fromberg where the Public Works Director is responsible not only for operating the wastewater system, but also for the drinking water system, garbage disposal, snow plowing, and parks just to name a few.

Great West and the Town worked with Nexom, the developer of the SAGR system, to design a lagoon system that would be followed by a SAGR polishing reactor that will be simple to operate and maintain and will allow consistent removal and low effluent levels for BOD, TSS, and Ammonia.

The SAGR allows the system to overcome the factors in typical lagoon systems that would otherwise prevent nitrification.

- When facultative lagoons freeze, atmospheric oxygen is no longer available to support the nitrifying bacteria.

- Nitrifying bacteria thrive when they have a surface to grow on, which is not abundant in a lagoon system.

- Heterotrophic bacteria that consume BOD dominate nitrifying bacteria. As a result, it’s difficult for nitrification to take place before BOD levels are lowered significantly.

- In cold temperatures, the heterotroph metabolism slows, which requires more lagoon retention time for BOD removal and reduces the available retention time for nitrification to take place.

- As water temperatures drop, nitrifying bacteria have a lower metabolism and reproduction rate and new biomass does not develop quickly enough to overcome the reduced consumption of ammonia occurring as a result of the lower metabolism.

In order to overcome these factors, the SAGR provides an environment that promotes the growth of nitrifying bacteria. The SAGR is a fully aerated polishing reactor constructed of sacrificial wood walls lined with a synthetic liner and filled with a clean rock. Lagoon effluent flows horizontally through the bed, which is sized to provide full BOD polishing and nitrification regardless of temperature. The SAGR offers a step-feed process to prebuild and store nitrifying bacteria during months in which the water is warm, so they are in place when winter temperatures arrive. The rock in the bed provides surface area

to support nitrifying bacteria growth and buffer the water temperature to avoid shocking the bacteria with cold influent.

Construction of the project was completed in 2018 and represented the first SAGR system constructed in Montana. Since going on-line, the system has consistently produced treated effluent with BOD5 levels below 10 mg/L, non-detectable TSS levels, and ammonia levels less than 0.10 mg/L.

Construction of the project was completed in 2018 and represented the first SAGR system constructed in Montana. Since going on-line, the system has consistently produced treated effluent with BOD5 levels below 10 mg/L, non-detectable TSS levels, and ammonia levels less than 0.10 mg/L.

This project provides long-term sustainable benefits to the environment by eliminating the discharge of inadequately treated wastewater into the Clark Fork of the Yellowstone River. The project also addressed issues related to the existing lagoons, which were unlined and leaking significant amount of untreated or partially treated wastewater into area groundwater and surface water. Additionally, using this innovative technology, the Town was able to save money in capital expenses as well as annual operation and maintenance costs by implementing a solution that cost less to construct and to maintain than other alternatives considered.

The total project cost for the design and construction of the new wastewater treatment system was $3.27 million. To offset these costs and to keep user rates reasonable, Great West assisted the Town in securing over $2.4 million in grants funds from the Treasure State Endowment Program (TSEP), the Department of Natural Resources Renewable Resources Grant and Loan Program (RRGL), the Community Development Block Grant Program (CDBG), and the United States Department of Agriculture Rural Development Program (RD).

LATEST NEWS

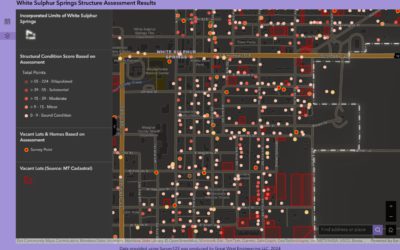

Beyond the Blueprint: How GIS Enhances Engineering & Planning Solutions

Geographic Information Systems (GIS) have become an essential tool for communities striving to make smarter, data-driven decisions. From infrastructure planning to public engagement, GIS provides a dynamic way to visualize, analyze, and manage data across a wide range...

Yearly ROSE Award Winners

At Great West Engineering, we take pride in recognizing the dedication and hard work of our team. Each year, the Recognition of Special Effort (ROSE) award honors employees who go above and beyond—those who step up, make a difference, and inspire those around them....

Why Transportation Planning Matters

Transportation planning is the collaborative process of evaluating the current state of a transportation network at a local, state, or regional level, identifying future transportation needs, and outlining implementation and funding strategies to align with...